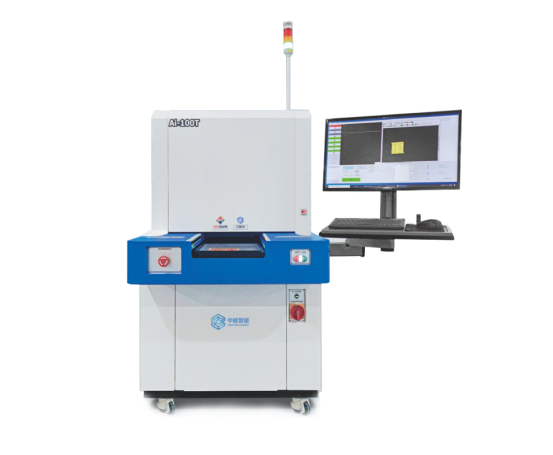

中能A9001 3D AOI外观检查机 中能智能

■适用范围 Scope of application

▪提取高度的测量数据,使用者可直观地检出在传统2D AOI上难以检测的引脚翘曲、组件倾斜等不良。并且针对组件大小、缺件、引脚翘曲、侧立、立碑、反面、极性、错件、焊点、连锡、引脚缺失、引脚板弯、桥接、文字检查(OCR,OCV)、色环电阻等所有不良类型均可检测出。

■特点 haracteristic

▪SMT制造工程检测设备市场的PARMI,通过向合作伙伴提供AI智能系统,让工程管理更加高效智能。SPl前/后端和AI智能系统的融合,不间断接送数据,确保生产率和品质的提高;更重要的是摆脱了SPI起初时的检查功能。先进的CLS工程改善,是SMT产线中实用的功能。

联系方式:

电话:0755-23274059

网址:http://www.cnengb.com

地址:深圳市宝安区西乡街道固戍二路中能产业园一楼(直接导航:中能智能产业园)

-

■适用范围 Scope of application

▪提取高度的测量数据,使用者可直观地检出在传统2D AOI上难以检测的引脚翘曲、组件倾斜等不良。并且针对组件大小、缺件、引脚翘曲、侧立、立碑、反面、极性、错件、焊点、连锡、引脚缺失、引脚板弯、桥接、文字检查(OCR,OCV)、色环电阻等所有不良类型均可检测出。

English

▪The height of the measurement data is extracted, and the user can intuitively detect the defects such as pin warping and component tilt that are difficult to detect on the traditional 2D AOI. And for component size, missing parts, pin warping, side erection, erection, reverse, polarity, wrong parts, welding points, even tin, pin missing, pin bending, bridge connection, text check(OCR, OCV), color ring resistance, and all other bad types can be perfectly detected.

■特点 haracteristic

▪SMT制造工程检测设备市场的PARMI,通过向合作伙伴提供AI智能系统,让工程管理更加高效智能。SPl前/后端和AI智能系统的融合,不间断接送数据,确保生产率和品质的提高;更重要的是摆脱了SPI起初时的检查功能。先进的CLS工程改善,是SMT产线中实用的功能。

English

▪PARMI, which leads the testing equipment market in the SMT manufacturing engineering of the IT industry, provides unprecedented engineering management through the provision of Close Loop systems to partners. The integration of SPI front/back end and Closed Loop system, continuous data transfer to ensure productivity and quality improvement; more importantly, get rid of the SPI initial inspection function. The advanced CLS engineering improvement will become the best and epoch- making function in the future SMT production line.

■机器参数 Parameters

Model

Xceed

Xceed L

Xceed XL

Xceed D

TRSC-

Measuring Principle

Shadow Free Dual Laser Optic al Triangulation

Camera System

4 Mega Pixel

IIIumination

RGB LED 3

Scan Speed(sq.cm/sec)

65sq.cm/sec

*X-Y Resolution(μm)

14*14μm

Lateral Length(mm)

32mm

Height Resolution(μm)

0.4μm

Performance

Height Repeatability

3 Sigma<3μm/Height

Height Accuracy

5um

Measurement

Inspection Type

Dimension,Missing,Misalignment(X/Y/Rotation),Wrong(Body),Side Mount,Tombs tone,Text(OCV/OCR),

Wrong(Matching),Solder Joint,Lead Lift,Lead Missing,Lead Offset,Bridge,Col or band,Pin,Coplanarity

PCB Warpage

±5mm(2%)

Barcode

1D/2D Barcode Inspection using TRSC-I

Max.Component Height

40mm

Board Dimension

Minimum Size(mm)

50*50

*Maximum Size(mm)

410*350 510*510 810*610 410*320

Board Thickness

0.4~5 0.4~5 0.4~10 0.4~5

Maximum Board Weight(kg)

2kg 4kg 6kg 2kg

TOP/Bottom Edge Clearance(mm/mm)

2.5/4.0 2.5/4.0 2.5/4.0 2.5/4.0

TOP side/Under side Clearance

50/50 50/50 50/50 40/30

System Dimension

*Dimensions(W*D*H)

850*1205*1525 950*1365*1525 1310*1540*1525 850*1580*1510

Weight(kg)

750kg 900kg 1100kg 950kg

Conveyor Height(mm)

860~970

Conveyor Speed Range

300~1000mm/sec

Flow Direction

L to R,R to L Factory Setting

Conveyor Width Adjusting

Auto

-